Air

is a mixture of different gases. The gases that make up the air include

nitrogen, oxygen, carbon dioxide, noble gases (argon, helium, neon,

krypton and xenon) and a little water vapour. Air may also contain

traces of impurities such as carbon monoxide (CO), sulphur dioxide (SO2), hydrogen sulphide (H2S)

and other gases. The presence of these gases in air results in air

pollution. Table bellow shows the composition of air by volume. The

proportion of water vapour and impurities in air is very variable.

The Gases Present in Air and their Proportions

Name the gases present in air and their proportions

The

composition of air is not exactly the same everywhere. It changes

slightly from day to day and from place to place. There is more water

vapour in the air on a damp day and in air above water bodies such as

oceans, seas, lakes, rivers, etc. Over busy cities and industrial areas

there is more carbon dioxide. But the uneven heating of the earth's

surface by the sun causes the air to move continually, resulting in

winds. The resultant winds spread the pollutants around.

The percentage composition of air by volume

| Gas | Approximate percentage |

| Nitrogen | 78.00% |

| Oxygen | 21.00% |

| Noble (rare) gases mainly argon | 0.94% |

| Carbon dioxide | 0.03% |

| Water vapour | 0 – 4% |

The Presence of Different Gases in Air

Demonstrate the presence of different gases in air

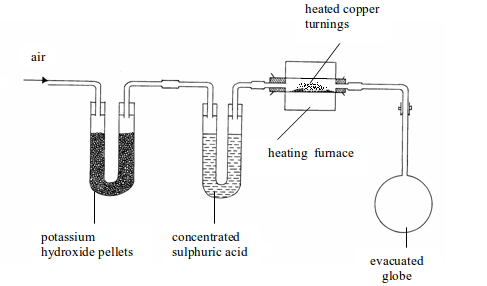

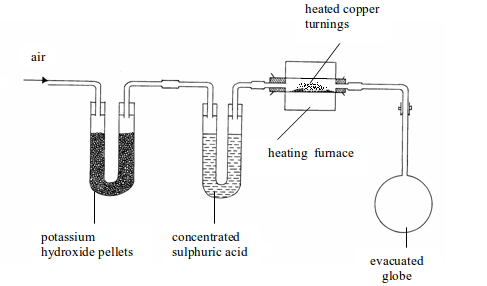

The determination of air by mass was carried out by Dumas in 1841. The apparatus used consists of three units as shown bellow.

The three parts of the apparatus include the following:

Determination of the composition of air by weight

- Several

U-tubes containing potassium hydroxide pellets to remove carbon dioxide

(only one tube shown in the figure for simplicity).

- Another set of U-tubes containing concentrated sulphuric acid to remove water vapour (only one tube shown in the figure).

- A heated, weighed glass tube containing finely divided copper to absorb oxygen.

The

three parts of the apparatus would, therefore, remove all carbon

dioxide, water vapour and oxygen contained in air. The remaining gas

which enters the weighed evacuated flask (globe) will be atmospheric

nitrogen and, of course, plus the rare gases. The copper will have

reacted with all oxygen to form copper (II) oxide. The increase in mass

of the copper will give the mass of oxygen. The increase in weight of

the globe will be due to the weight of nitrogen and the rare gases. If

we neglect the weight of carbon dioxide, the percentage of oxygen by

mass (weight) in dry, pure air is 23.2% and the remaining 76.8% is the

percentage of nitrogen and rare gases.

The Percentage of Oxygen in Air Experimentally

Determine the percentage of oxygen in air experimentally

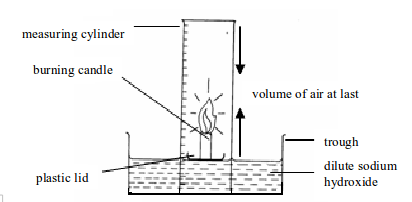

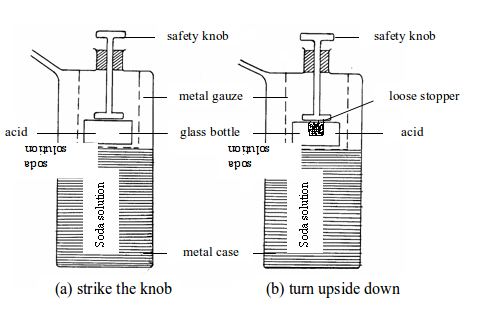

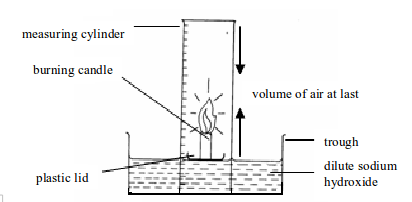

1. Experiment. Determination of the presence and proportion of oxygen in air by combustion of a candle

Method

- Place

a small candle on a plastic lid or any object that can float. Then set

up the apparatus as shown in figure bellow. Sodium hydroxide is used in

order to absorb the carbon dioxide gas produced by a burning candle.

- Light

the candle and place the measuring cylinder over the top. Note the

level of sodium hydroxide solution in the measuring cylinder at the

start. A candle will stop burning (go off) once all the oxygen in the

cylinder is used up.

- When the candle goes off, leave the

apparatus to cool to room temperature. The purpose of cooling is to let

the heated and expanded air to return to its normal condition. Then note

the level of sodium hydroxide solution in the measuring cylinder.

.

Determining the presence and percentage composition of oxygen in air by burning a candle

The

oxygen in air enclosed in the measuring cylinder is used to burn the

candle to produce carbon dioxide gas. The carbon dioxide so produced

dissolves in sodium hydroxide solution. The dissolved carbon dioxide

causes the level of sodium hydroxide solution to rise up. The oxygen gas

used to burn the candle is practically equal to the amount of carbon

dioxide produced. This fact is, therefore, used to calculate the

percentage of oxygen in air.

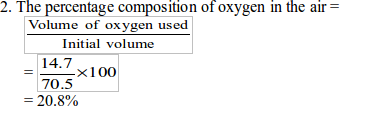

Model results

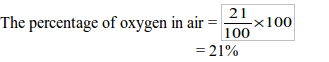

In the experiment, the initial volume of air was found to be 70.5 cm3 and the final volume was 55 cm3. The percentage of oxygen in the air is calculated in two steps:

1.

To find the volume of oxygen used up to burn the candle (which is

practically equal to the volume of carbon dioxide produced and then

absorbed by sodium hydroxide), we subtract the final volume of air from

the initial volume

Volume or oxygen used = Initial volume of air – final volume of air

Therefore, the volume of oxygen used for combustion of the candle = 14.7 cm.

Alternatively,

the volume of oxygen used up can be calculated by subtracting the

initial volume of sodium hydroxide solution from the final volume. That

is: Volume of oxygen used = final volume of sodium hydroxide – initial

volume of sodium hydroxide = Volume of carbon dioxide dissolved in

sodium hydroxide.

Therefore, the percentage of oxygen =

In practice, it is difficult to get an accurate result with the above experiment.

This is due to a number of reasons such as:

- Not all the carbon dioxide is absorbed by the sodium hydroxide.

- The candle may go out (stop burning) before all the oxygen is used up due to accumulation of carbon dioxide in the cylinder.

- The

heating of the air inside the measuring cylinder causes the gases to

expand. This is why it is essential that the gases be allowed to cool to

room temperature before reading the level.

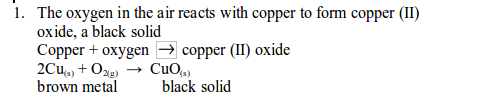

Experiment with combustion of copper in air gives

the more accurate results than the combustion of the candle. The copper

reacts with oxygen in the air to give copper (II) oxide.

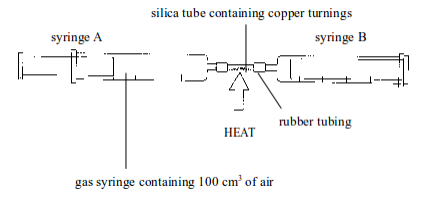

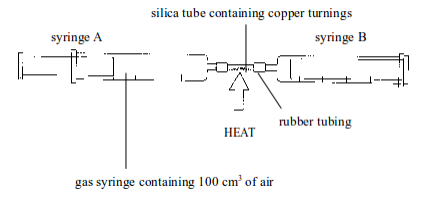

2. Experiment . Determination of the presence and proportion of oxygen in air by the combustion of copper in air

Method

- Set up the apparatus as shown in figure bellow. Syringe A should contain 100 cm of air, syringe B should be empty.

- Heat

the copper strongly and pass the air from syringe A back and forth (by

pushing the piston of the syringe inward and outward) over the copper

turnings a few times. Allow the air to cool and measure the volume of

air in syringe A.

- Repeat the heating and cooling until the

volume of air that remains in syringe A is constant. The copper is

heated and cooled several times to ensure that it reacts with all oxygen

in the sample of air.

`

Determining the presence and percentage composition of oxygen in air by heating copper

Observations and findings

2.

The final volume of air in the syringe, at the end of the experiment,

is less than that of the original volume. This is because oxygen in the

original air has combined with copper

The volume of air in the syringe at different heating and cooling is as shown below:

Initial volume before heating = 100

Volume after first heating and cooling = 82

Volume after third heating and cooling = 79

The volume of oxygen used up = Initial volume of air before cooling - volume of air after the last heating and cooling

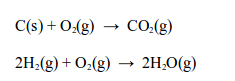

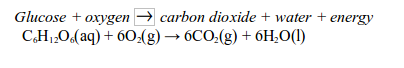

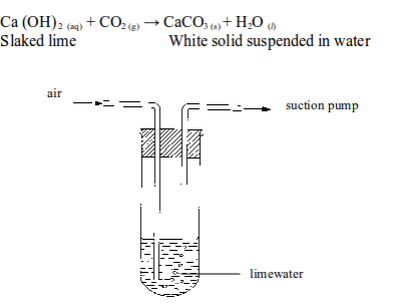

The presence of carbon dioxide in air

Carbon

dioxide is present in air to the extent of 0.03% by volume. The gas is

formed during the combustion of all common fuels – wood, coal, coke,

natural gas, petrol, diesel, paraffin oil, etc, all of which contain

carbon.

It

is breathed out as a waste product of respiration by all animals. All

sorts of combustion and burning produce carbon dioxide. The gas produced

by all these processes accumulates in air. However, the amount of

carbon dioxide in air remains constant instead of the tremendous

quantities released into the atmosphere. This is because plants take up

carbon dioxide. They then convert it into complex starchy compounds

during photosynthesis. The gas also dissolves in ocean water and other

water bodies.

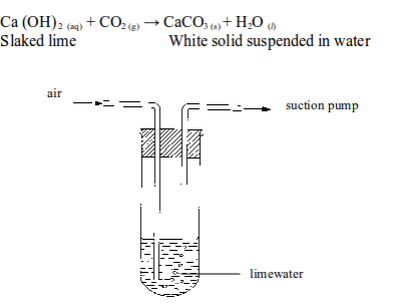

The

presence of carbon dioxide in air can be shown by passing air through a

test tube containing some limewater (figure 6.5). After a time, the

limewater turns milky. This shows the presence of carbon dioxide.

The reaction involved is as follows:

``

Testing for the presence of carbon dioxide in air

The presence of water vapour in air

Water

vapour is present in air in varying quantities. It is given off by

evaporation from the oceans, lakes and rivers. The presence of water

vapour in air can be demonstrated by exposing deliquescent substances to

the air on a watch glass. These are substances which when exposed to

air tend to absorb much moisture from the air, dissolve in that

moisture, and finally form a solution. Examples of deliquescent

substances include calcium chloride, sodium hydroxide and phosphorous

pentoxide.

The

resulting solution is distilled. The colourless liquid obtained from

distillation may be proved to be water by various water tests such as

use of cobalt chloride paper or anhydrous copper (II) sulphate. The

cobalt chloride paper turns from blue to pink in the presence of water.

The white anhydrous copper (II) sulphate turns blue. Any of the two

tests confirms the presence of water.

Alternatively,

one may expose the anhydrous copper (II) sulphate salt to open air

straight away for quite some time and then observe any change in its

colour and/or form. Upon absorption of water vapour from the air, the

white, powdery and anhydrous copper sulphate salt turns into hydrated

blue crystals.

About

1% of the air by volume is made up of the noble gases. The most

abundant of the noble gases is argon. Others are neon, xenon, krypton

and helium. The proportion of these four is very minute. Argon and neon

are used in “gas-filled” electric light bulbs and coloured “neon”

electrical signs. They are obtained from liquefied air.

The

air always contains small quantities of many gases. Such gases include

hydrogen sulphide, sulphur dioxide, as well as dust and other solid

particles, especially in industrial areas. These gases are given off

during the combustion of coal, and the fuels resulting from coal.

SEPARATION OF AIR INTO ITS CONSTITUENT GASES

The

air we breathe is necessary to keep us alive. It is also a chemical

resource. Oxygen is used in steel making, and nitrogen is used in making

fertilizers. To use these gases in this way, they must be separated

from the atmospheric air. Air, as we studied in chapter 5, is a mixture

of different gases. The method used to separate its constituent gases is

fractional distillation. The gases have to be liquefied so that the

mixture can be fractionally distilled.

The

process of separating the air into its constituent gases is difficult.

It cannot be done in the laboratory. It is only done in industry. The

chemical industry needs the gases from the air in their pure form.

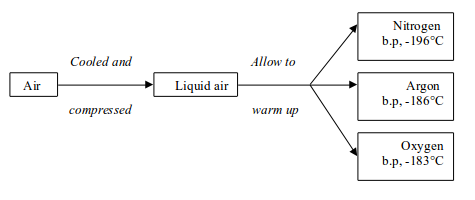

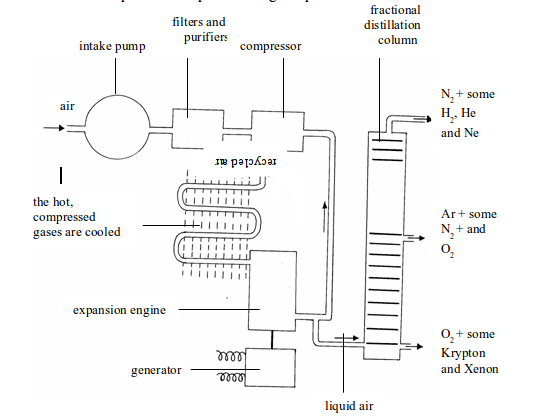

The fractional distillation of air involves essentially two stages:

- First, the air must be cooled until it turns into a liquid.

- Then, the liquid air is allowed to warm up again. The various gases boil off at different temperatures

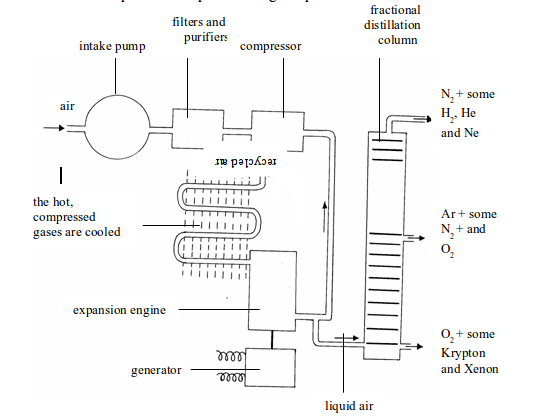

Stage 1: Liquefaction of air

- Air is filtered to remove any dust particles (purification).

- The air is cooled to -180°C to remove the water vapour and carbon dioxide.

- The air is then compressed to 100-150 atmospheres. As the compressed air gets very hot, it has to be cooled.

- The

compressed cooled air is allowed to expand rapidly. The rapid expansion

cools the air to very low temperatures, and the liquid drops out. At

-200°C, only helium and neon remain as gases. The cold gases are used to

cool the compressed air.

Stage 2: Fractional distillation of liquid air

The

air is cooled and compressed to form liquid air. The liquid air is

allowed to warm up. Nitrogen boils off first because it has a low

boiling point, -196°C. Argon follows by boiling at -186°C and finally

oxygen at -183°C

Figure above illustrates all the steps that take place during the process.

Fractional distillation of liquid air

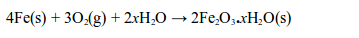

The Concept of Rusting

Explain the concept of rusting

Rusting

is the name given to the oxidation of iron or steel in damp air. It is

also called corrosion. Rust is hydrated iron (III) oxide. It is a soft,

crumbly solid and hence weakens the structure of iron and steel. During

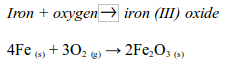

rusting, iron reacts with oxygen to form brown iron (III) oxide

At the same time the iron (III) oxide reacts with water to form hydrated iron (III) oxide (or rust):

Note: The x in

the equation indicates that the number of water molecules in the

hydrated iron (III) oxide can vary. So, both oxygen and water are

needed to cause rusting of iron.

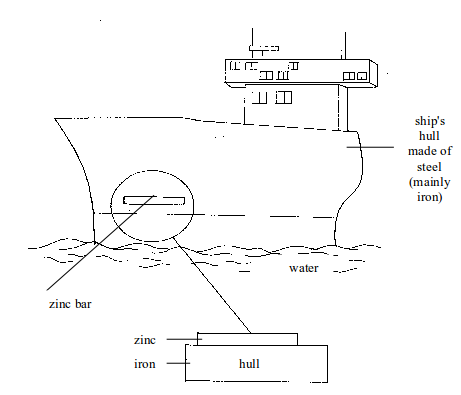

Rusting

is a serious economic problem. Large sums of money are spent each year

to replace damaged iron and steel structures, or protecting structures

from such damages. Rusting of bridges, corrugated iron sheets on house

roofs, containers, articles, etc. require an expenditure of big sums of

money as well as labour for replacement. Rust weakens structures such as

car bodies, iron railings, and ships’ hulls, and shortens their useful

life. Preventing it can cost a lot of money. All efforts must be made to

stop iron or steel items from rusting. This can be achieved if we know

the conditions necessary for iron to rust.

The Conditions Necessary for Iron to Rust

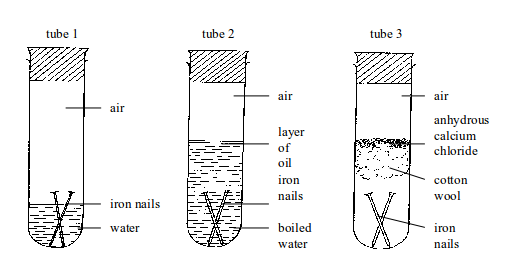

Demonstrate the conditions necessary for iron to rust

When

iron is left in contact with both water and oxygen (or air), it reacts

to form hydrated iron (III) oxide. Iron will not rust on exposure to dry

air or air-free water (water that has been boiled to expel all

dissolved air) only. However, iron will easily and readily rust in water

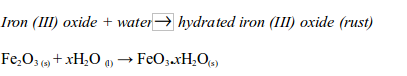

that has dissolved air in it. In figure 6.8, only the iron nail that is

in contact with both water and air rusts. Therefore, rusting will only

occur in the presence of both water and oxygen. If one of the two

conditions is excluded, in one way or another, rusting will not take

place at all.

Testing for conditions necessary for iron rusting

Nails in tube 1 will rust. Nails in tubes 2 and 3 will not rust.

In

tube 1, nails are in contact with both water and air (oxygen). In tube

2, the water has been boiled to expel the dissolved air. In addition,

any air above the water is prevented from dissolving in boiled water by a

layer of oil. So, the nails are completely shielded away from air.

Therefore, rusting is impossible. In tube 3, nails are in contact with

air only. The moisture present in air is absorbed by anhydrous calcium

chloride. Any moisture that might have been absorbed by the anhydrous

calcium chloride is prevented from reaching the nails by a tuft of

cotton wool. The cotton wool also absorbs some moisture directly from

the air. Therefore, tube 3 will always carry dry air (moisture-free

air). Hence, no rusting of iron nails occurs.

This

experiment demonstrates the fact that for iron to rust, both water and

air (oxygen) must be present. If one of these conditions is controlled,

no rusting can take place.

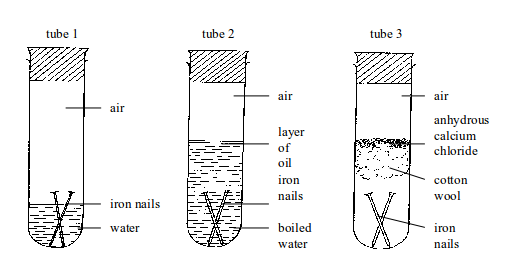

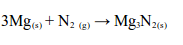

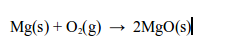

Similarity between rusting and burning

Chemically,

rusting and burning are similar processes in that they both require

oxygen. Consider the burning of magnesium to give magnesium oxide.

In this process, magnesium combines with the oxygen of the air to form magnesium oxide.

During rusting, iron combines with oxygen of the air in the presence of water to form brown hydrated iron (III) oxide, "rust."

In

addition, the two processes, burning and rusting, are exactly similar

in that they both generate heat. The only difference is in the time

required for each of the two processes to take place. During rusting

heat is given out, but without being noticed because of its slower rate

of production. Burning produces noticeable heat and light.

The Different Methods of Preventing Iron from Rustin

Describe the different methods of preventing iron from rusting

We

have learned that for iron to rust there must be direct contact between

the iron and both water and oxygen from the air. Therefore, in order to

stop rusting we must protect iron from either water (moisture) or

oxygen (air) or both. The following are some of the methods used to

prevent iron from rusting:

Silica is a common name for silicon dioxide (SiO

2).

Silica gel is a granular, vitreous, highly porous form of silica made

synthetically from sodium silicate. Despite its name, silica gel is a

solid. It is used as a desiccant, which absorbs moisture to prevent

rusting of iron items or articles. Most often, a small bag of silica gel

is put inside bags or boxes used for storing or carrying iron items to

absorb any moisture that may cause rusting.