FUEL AND ENERGY

what is fuel?

Renewable

energy sources include biomass, geothermal energy, hydroelectric power,

solar energy, wind energy, and chemical energy from wood and charcoal.

These are called renewable energy sources because they are replenished

within a short time. Day after day, the sun shines, wind blows, river

flows and trees are planted. We use renewable energy sources mainly to

generate electricity.

In Tanzania most of the energy comes from non-renewable sources. Coal, petroleum, natural gas, propane and uranium are examples of non-renewable energy sources. These fuels are used to generate electricity, heat our homes, move our cars and manufacture many kinds of products. These resources are called non-renewable because they cannot be replenished within a short time. They run out eventually. Once, for example, coal or petroleum is depleted, it may take millions of years to be replaced. So, these are non-renewable energy sources.

BIOGAS

Biogas

is a gaseous fuel produced by the decomposition of organic matter

(biomass). Under anaerobic conditions, bacteria feed on waste organic

products, such as animal manure and straw, and make them decay. The

product formed from this decay is called biogas, which consists mainly

of methane, though other gases such as carbon dioxide, ammonia, etc, may

also be produced in very small quantities. The biogas produced can be

used as a fuel for cooking, heating, etc.

Raw

materials for biogas production may be obtained from a variety of

sources, which include livestock and poultry wastes, crop residues, food

processing and paper wastes, and materials such as aquatic weeds, water

hyacinth, filamentous algae, and seaweeds.

The Working Mechanism of Biogas Plant

Explain the working mechanism of biogas plant

The

organic waste products are fed in a biogas plant. Prior to feeding the

material into the plant, the raw material (domestic poultry wastes and

manure) to water ratio should be adjusted to 1:1 i.e. 100 kg of excreta

to 100 kg of water. Then adequate population of both the acid-forming

and methanogenic bacteria are added.

The bacteria anaerobically feed on the liquid slurry in the digester. The major product of this microbial decomposition is biogas, which largely contain methane gas. The gas so produced is collected in the gas holder and then taped off. The gas is used as a fuel for cooking, heating and other general purposes.

The biological and chemical conditions necessary for biogas production

Domestic

sewage and animal and poultry wastes are examples of the nitrogen-rich

materials that provide nutrients for the growth and multiplication of

the anaerobic organisms. On the other hand, nitrogen-poor materials like

green grass, maize stovers, etc are rich in carbohydrates that are

essential for gas production. However, excess availability of nitrogen

leads to the formation of ammonia gas, the concentration of which

inhibits further microbial growth. This can be corrected by dilution or

adding just enough of the nitrogen-rich materials at the beginning.

In

practice it is important to maintain, by weight, a C:N close to 30:1

for achieving an optimum rate of digestion. The C:N can be manipulated

by combining materials low in carbon with those that are high in

nitrogen, and vice versa.

A pH range for substantial anaerobic digestion is 6.0 – 8.0. Efficient digestion occurs at a pH near to neutral (pH 7.0). Low pH may be corrected by dilution or by addition of lime.

To

ensure maximum digestion, stirring of the fermentation material is

necessary. Agitation (stirring) can be done either mechanically with a

plunger or by means of rotational spraying of fresh organic wastes.

Agitation ensures exposure of new surfaces to bacterial action. It also

promotes uniform dispersion of the organic materials throughout the

fermentation liquor, thereby accelerating digestion.

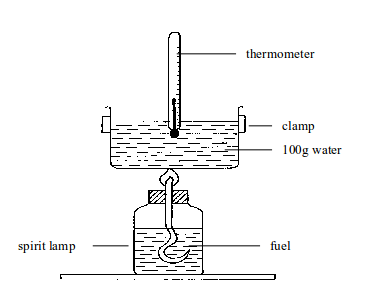

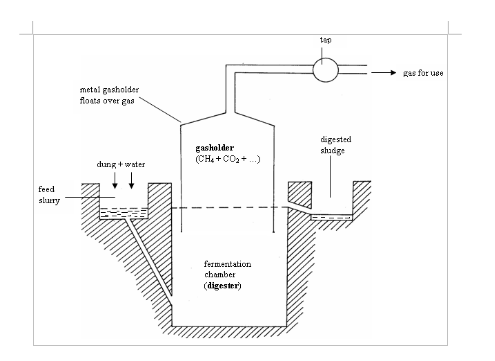

A Model of Biogas Plant

Construct a model of biogas plant

The

biogas plant consists of two components: the digester (or fermentation

tank) and a gas holder. The digester is a cube-shaped or cylindrical

waterproof container with an inlet into which the fermentable mixture is

introduced in the form of liquid slurry. The gas holder is normally an

airproof steel container that floats on the fermentation mix. By

floating like a ball on the fermentation mix, the gas holder cuts off

air to the digester (anaerobiosis) and collects the gas generated. As a

safety measure, it is common to bury the digester in the ground or to

use a green house covering.

Structure of the biogas plant

The Use of Biogas in Environmental Conservation

Explain the use of biogas in environmental conservation

Environmental

conservation is a major concern in life. We need to live in a clean and

health environment so as to enjoy our lives better. The use of biogas

as an alternative source of energy is essential in environmental

conservation due to a number of reasons. These are some of the reasons:

- Biogas does not produce much smoke or ash, which could otherwise pollute the atmosphere or land. When the gas is burned it produces very little smoke and no ash as compared to other sources of fuel such as wood.

- The use of biogas for cooking and heating prevents the cutting down of trees to harvest firewood, or burn charcoal for fuel, a practice that could result to soil erosion, drought, etc. Hence, using the biogas as fuel helps to conserve the environment as no more cutting of trees may be done.

- Using cow dung, poultry manure and other excreta for biogas production helps keep the environment clean because these materials are put into alternative use instead of just being dumped on land, a fact that could lead to pollution of the environment.

- Some biomass employed in biogas production is toxic and harmful. By letting these materials be digested by bacteria, they may be turned into non-toxic materials that are harmless to humans, plants, animals and soil.

- The excreta used for production of biogas produce foul smell if not properly disposed of. Using this excrete to generate biogas means no more bad smell in air.

- Health hazards are associated with the use of sludge from untreated human excreta as fertilizer. In general, a digestion time of 14 days at 35ºC is effective in killing the enteric bacterial pathogens and the enteric group of viruses. In this context, therefore, biogas production would provide a public health benefit beyond that of any other treatment in managing the rural health and environment of developing countries.